تفاصيل المنتج:

شروط الدفع والشحن:

|

| Name: | cheap plastic prototype by vacuum casting with silicone mold for low volume production | Business Type: | Manufacturer & Trading Company |

|---|---|---|---|

| Quality control: | strict inspection before shipping | avaliable files: | Auto CAD , igs ,stp ,step ,x-t ,prt ,sldprt , |

| Quotation lead time: | within 24 hours | Materials: | resin ,transparent ,white resin |

| Tolerance: | +/- 0.1 )mm | Express Way: | DHL , TNT , UPS , Fedex and shipping by sea . |

| الأسعار: | reasonable and negotiate | QC report: | files and copy files |

Plastic Prototype Vacuum Injection Moulding / Vacuum Formed Products

Volume production is very important for testing the market .because after prototype ,we dont know how will going on this product . so samll batch production will get more information of this product .

advantage

1: Cheap price for samll batch production

2: fast leading and good quanlity

3: Silicone mold for Marketing

So the vacuum casting is the best way for plastic samll batch production

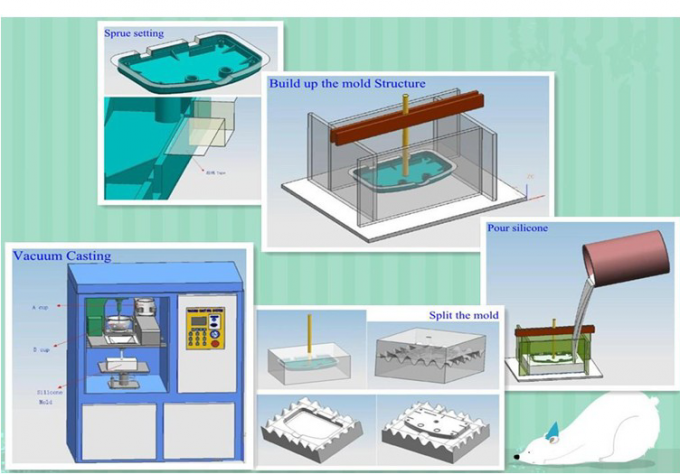

what is vacuum casting ?

Vacuum-mode, also called vacuum injection mold. Is under vacuum conditions castable degassed, stirring, preheating, injection type, and the second curing process 2-3 hours in a thermostat 60 ℃ -80 ℃ in. This method is particularly suitable for small batch production. Is a cost effective solution to solve the short pilot production and small-volume manufacturing, but also to meet some of the more complex structure of the engineering model of functional testing proofing.

Silicone mold is a vacuum in one of the peritoneum in a short time to solve the functional products of small batch production of low-cost solution. From soft to hard plastic, a broad choice of resin material makes silicone products complex mode and injection molded parts is almost comparable. In addition, high-quality surface and relatively low cost advantage is the best choice for small batch production, marketing, functional testing, exhibiting samples

Why choose Strongd ?

1. High quality

2. Prototype factory directly

3. Advanced tecnology and equipment .

4. Certificate : ISO9001:2008